NOVATHERM 2 – ANOTHER SUCCESSFUL EDITION OF THE

“INNOVATIVE SOLUTIONS IN HEAT TREATING” SEMINAR

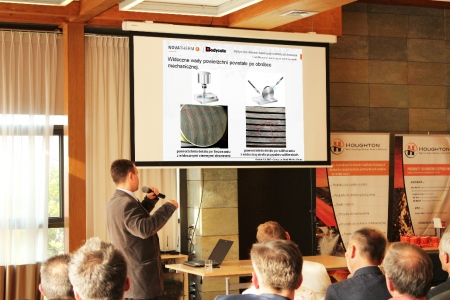

Three years after the launch of the “Innovative Solutions in Heat Treating” Seminar, Nitrex Metal in conjunction with United Process Controls and the Institute of Precision Mechanics, held a second successful edition at the Black Forest Palace Hotel in Central Poland on October 8-9, 2015. The seminar relies mainly on leading academic researchers and industry practitioners from around the world to deliver high quality content on the latest innovations that improve manufacturing quality and efficiency.

Presentation titles ranged from very specific themes such as “High nitrogen carbonitriding – Improving energy efficiency of power train components” and “Simulation of nitriding and nitrocarburizing processes”, to more general ones, such as “Importance of flow control in heat treatment processes” and “Global heat treating trends of the 4th industrial revolution”. In addition to improving their knowledge of available technologies, over 75 participants had the opportunity to form closer relationships with industry/academic players from diverse countries and continents.

Due to popular demand, a third edition has been planned for 2018.

Join us at the third edition of the seminar.

Presentation titles

Monitoring the growth of layers in nitriding processes – Nitran project

Prof. Jerzy Michalski, PhD – Institute of Precision Mechanics (IMP)

Ion nitriding of X2CrNiMo17-12-2 austenitic steel

Tadeusz Frączek – Czestochowa University of Technology

High nitrogen carbonitriding – Improving energy efficiency of power train components

Jens Baumann – Process-Electronic GmbH (a member of UPC)

The benefits of ion nitriding applied to ASz62IR grade aerospace engine cylinder liners

Maciej Olejnik – WSK PZL Kalisz

Achieving high corrosion resistance by controlled gas nitriding/nitrocarburizing and post oxidation

Marcin Stokłosa – Nitrex Metal Sp. z o.o

Control and adjustment of Nitrogen/Hydrogen‐blends in heat treatment atmospheres and their impact on metal surface properties

Guido Plicht – Air Products

Control and adjustment of Nitrogen/Hydrogen-blends in heat treatment atmospheres and their impact on metal surface properties

Enrico Grisenti – Datapaq

Global heat treating trends of the 4th industrial revolution

Janusz Kowalewski – ALD Dynatech Furnaces

Simulation of nitriding and nitrocarburizing processes

Karl-Michael Winter – Process-Electronic GmbH (a member of UPC)

The influence of machining on nitriding results – Practical applications

Jakub Jasiński – Bodycote Polska /Poland

Modifying the surface with CrN coatings using linear magnetron sputtering technology

Marek Betiuk – Institute of Precision Mechanics

Current state of standardization in the field of nitriding and nitrocarburizing

Dieter Liedtke – Honorary Member of AWT (IMP)

Controlled gas nitriding for anti-corrosion properties

Piotr Wach Instytut Mechaniki Precyzyjnej (IMP)

Surface roughness changes during gaseous nitriding

Dimitri Koschel – Nitrex Metal Inc.

Modification of nitride layers by laser

Michał Kulka – Poznan University of Technology

Cleaning technologies in the heat treatment industry

Damian Sputo – Dürr Schenck – Polska/Poland

Importance of flow control in heat treatment processes

Paweł Ficek – Process-Electronic Sp. z o.o. (a member of UPC)